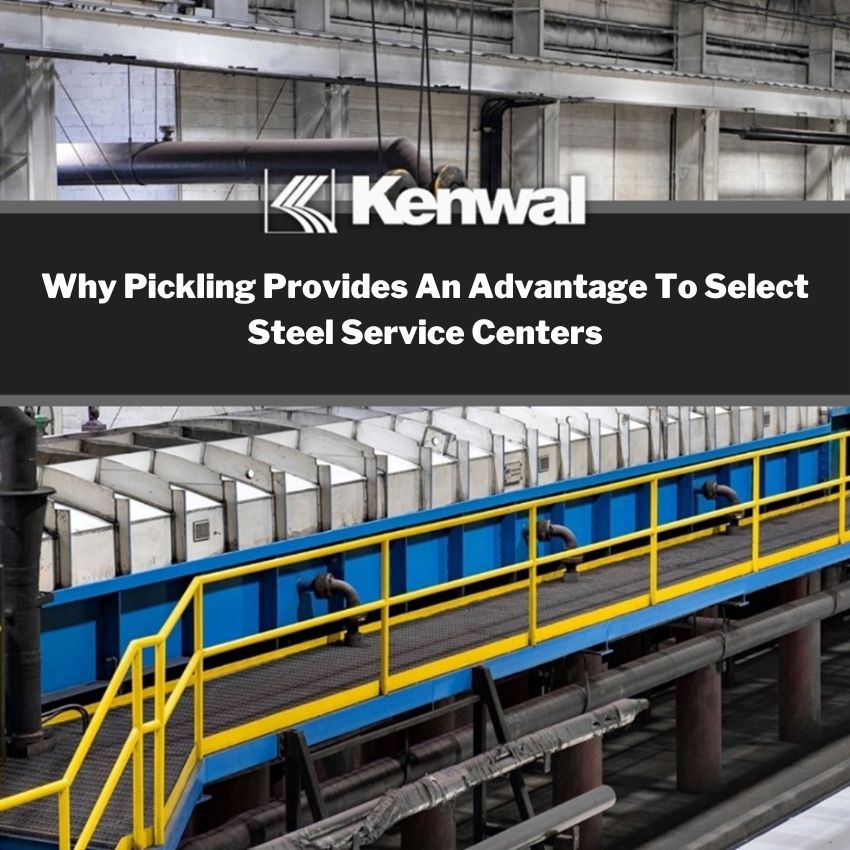

With continually increasing demand for hot rolled base metal products, the need for pickling in the steel industry has gained considerable traction providing a unique advantage to service centers with pickling capability, particularly those focused on advanced high strength steel. Which raises the questions, why do steel service centers pickle steel, and what makes pickled steel so essential?

Let Kenwal’s industry expertise explain the importance of why steel service centers pickle steel, how this vital process works, and how it improves the quality of steel products and its many applications.

Why Select Steel Service Centers Pickle Steel

To begin, steel pickling is a chemical treatment that cleans steel by removing impurities, rust, and scale. This process creates a smooth, clean surface essential for improving the steel’s overall quality and performance. Detailed benefits of pickled steel include:

- Enhanced adhesion means better bonding for coatings and finishes.

- Improved corrosion resistance protecting steel from rust and decay.

- Better paintability by creating a smooth surface for even paint application.

- Increased weldability by removing contaminants that can affect welding quality.

- Enhanced formability making steel easier to shape and bend.

For example, in galvanizing processes, steel pickling is critical to ensure a clean surface, allowing the zinc coating to properly adhere. Without this step, the coating could be uneven, resulting in a substandard finish.

The Steel Pickling Process

As mentioned above, steel pickling is a treatment process where the metal is submerged into an acidic solution. This process effectively removes surface rust and mill scale, as the acid in the solution seeps into the surface gaps of the scale, allowing it to reach the base metal and dissolve the impurities. Once the mill scale is dissolved, it is then easily removed, resulting in a clean surface ready for further processing.

At Kenwal, we utilize advanced and proprietary processes to ensure the highest quality while pickling customer’s steel . Our process includes:

- Tension leveling ensuring a flat surface by removing residual stresses.

- Anti-coil break roll preventing damage during the pickling process.

- Parsytec automatic coil inspection utilizes advanced imaging to detect surface imperfections.

- X-ray gauging which precisely measures thickness to guarantee compliance with specifications.

- Electrostatic oiler applies a protective oil to enhance corrosion resistance and formability.

This thorough approach guarantees that the pickled steel meets the demanding standards required for various applications.

Applications of Pickled Steel

Pickled steel is widely used across multiple industries due to its superior surface quality and corrosion resistance. Common applications include:

- Automotive manufacturing: Hot rolled pickled steel is essential for producing lightweight and durable vehicles, contributing to improved fuel efficiency and performance.

- Appliance manufacturing: Pickled steel can be found in the inner components of many everyday appliances found in most commercial and residential kitchens, laundries, and bathrooms.

- Agricultural Equipment manufacturing: High strength steel products are critical in the farming and food processing industry.

- General manufacturing: Pickled steel is utilized in a variety of products, from office furniture to “big box” shelves and racking, where surface quality and performance are paramount.

- Construction: Steel products that require high corrosion resistance are crucial in building structures, bridges, and other infrastructure projects.

Its applications in Automotive, Appliance, Agriculture and other manufacturing and construction demonstrate its importance in producing lightweight, durable components, enhancing structural integrity, and ensuring high performance across a range of products.

Choose Kenwal for Your Pickled Steel Needs

The select steel service centers with pickling capability enhance product quality and meet the evolving demands of various industries. At Kenwal, we combine advanced technology with decades of expertise to deliver high-quality pickled steel tailored to your specific manufacturing requirements.

Kenwal’s commitment to precision and innovation ensures that you receive the best materials for your needs, whether for automotive, appliance, agricultural construction, or general manufacturing applications.

By partnering with Kenwal, you gain access to premium pickled steel that meets the highest industry standards, helping your business succeed in today’s competitive landscape. Trust Kenwal to provide superior steel products that drive performance, efficiency, and sustainability.

More about Kenwal Steel

With over 75 years of experience, Kenwal excels in providing premium pickled steel, on time. Whether you require hot rolled pickled steel or other steel products, Kenwal is your trusted partner. Our cutting-edge pickling line produces the highest-quality steel. Located within the same facility as our steel slitting operations, we streamline the processing of your coiled steel orders, ensuring you receive the pickled and oiled steel you need promptly.

We emphasize quality with our A2LA-certified lab, which guarantees that your steel’s properties — such as tensile strength, yield strength, and elongation — meet your manufacturing standards. With rigorous inspections, advanced customizable packaging, and strategic locations we provide timely delivery. Our industry expertise, coupled with IATF 16949 and ISO 14001 certifications, demonstrates our commitment to excellence. Trust Kenwal for your steel solutions.

Contact Kenwal Steel by filling out a form here or call 313-739-1000 today to discuss your next steel project!

Recent Comments