Key Takeaways

- Steel products for industrial applications are essential across industries. Such products are automotive, construction, and manufacturing, providing strength, durability, and versatility. The three primary categories include flat-rolled, long steel, and specialty steel — each catering to specific industrial needs.

- The steel industry continues to evolve with technological advancements, meeting sustainability goals and improving efficiency in various industrial applications.

- Partnering with an experienced steel service center like Kenwal Steel ensures access to premium materials, expert support, and reliable supply chain solutions.

Steel products for industrial applications play a vital role in shaping industries ranging from automotive to agriculture. The World Steel Association estimates that the global steel demand is expected to be “1.793 billion metric tons in 2024 and to increase further in 2025.” As manufacturers demand versatile, durable, and high-performing materials, steel remains a pillar of modern industrial innovation. Which begs the question, what are the steel products for industrial applications?

Let Kenwal’s 70 years of steel experience navigate you through the top three categories of steel products essential for industrial applications, which are flat-rolled steel, long steel, and specialty steel products.

1. Flat-Rolled Steel Products

To begin, flat-rolled steel products, such as hot rolled steel, cold rolled steel, and galvanized steel, are indispensable in industrial manufacturing. These products are known for their versatility, durability, and strength, making them ideal for industries such as automotive, electronics, and appliance manufacturing.

Key features:

- Hot rolled steel: Ideal for structural applications due to its malleability and strength, often used in heavy equipment and machinery. This type of steel is produced by rolling steel at high temperatures, resulting in a strong and durable material

- Cold rolled steel: Known for its smooth surface finish and precise dimensions. This steel is produced by rolling hot-rolled steel at lower temperatures, resulting in a smoother and more precise finish.

- Coated steel: This type of steel is coated with a protective layer, such as galvanized or galvanized annealed steel, to enhance its corrosion resistance. This coating is crucial for harsh environments.

According to Statista from 2000-2021, “more than 77 million metric tons of hot rolled flat steel products were made” by North American steel service centers. This statistic underscores the dominance of flat-rolled steel products for industrial applications, making them a leading category in the steel market.

2. Long Steel Products

Long steel products, including beams, rods, and bars, are the backbone of structural frameworks and load-bearing components in industries such as construction and infrastructure. These products are engineered to provide the strength and stability required for large-scale projects.

Applications:

- Beams: Bridges and skyscrapers rely on the strength and longevity of steel beams. Additionally, steel is a unique recyclable material that retains its quality with each recycling cycle, unlike plastic. Moreover, steel construction is more efficient, as scrap pieces can be welded together for smaller projects, reducing waste compared to wood.

- Rods and bars: Essential for reinforcing concrete structures and scaffolding, steel enhances concrete’s strength and durability. For example, without steel reinforcement, concrete is vulnerable to compressive and tensile stresses. Steel counteracts concrete’s weakness in tension, transforming it from “a brittle material to a ductile one.”

The demand for long steel products for industrial applications continues to grow, with the global market projected “to reach USD 1,012,105.9 million by 2030,” driven by demand in infrastructure projects. Ultimately, this solidifies long steel’s position as a fundamental component in the steel industry.

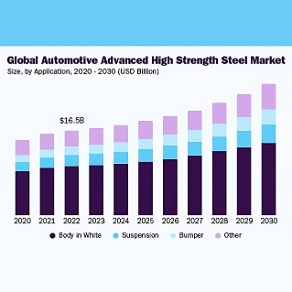

Global Automotive Advanced High Strength Steel Market Chart Attribution: https://www.grandviewresearch.com/industry-analysis/automotive-advanced-high-strength-steel-market-report

3. Specialty Steel Products

Specialty steel, such as ultra-high-strength steel (UHSS), advanced high-strength steel (AHSS), and alloyed steels, caters to industries requiring precision, high strength, heat resistance, and corrosion resistance. These steel products for industrial applications excel in challenging environments and cutting-edge innovations across multiple sectors.

Why specialty steel?

- UHSS and AHSS: Lightweight yet incredibly strong, these materials are transforming the automotive industry by enabling lightweighting while maintaining safety. In doing so, it not only reduces the vehicle’s weight, but it also “can increase fuel efficiency and decrease tailpipe emissions. The latest grades of AHSS have the potential to significantly reduce vehicle weight by 35.0-40.0% compared to that of traditional steel.” (Source: Grand View Research)

- Alloyed steels: Designed for extreme conditions, such as high temperatures or chemical exposure. For instance, interstitial alloys “tend to be less malleable than pure metal” making them ideal for construction due to its “remarkable resistance to compression.”

Depending on their structural makeup, alloys can have multiple functions:

- Chromium – creates harder steel

- Cobalt – builds more heat-resistant steel

- Manganese – improves the shear strength

- Nickel – increases resistance to corrosion

(Source: Professor Dave Explains)

Additionally, the advanced high strength steel market is anticipated to grow to “USD 44.5 billion by 2032 at a CAGR of 7.8%.,” while the alloy steel industry is expected to climb to “27.8 (USB billion) by 2032.” Both metals’ projected growth showcases how they are a staple in the market.

Steel products for industrial applications continue to be the foundation of industrial growth. With innovations in flat-rolled steel, long steel, and specialty steel products enabling industries to tackle challenges and achieve sustainability goals. Partnering with an expert steel service center ensures access to premium materials and cutting-edge support tailored to your industrial needs.

Why Choose Kenwal Steel?

With over 70 years of experience, Kenwal Steel is a leading provider of high-quality steel products, offering a diverse range of options to meet the ever-evolving demands of industrial applications.

Kenwal Steel’s commitment to excellence ensures that customers receive the highest quality products and services tailored to their unique industrial needs. They offer a comprehensive range of services focused on steel products for industrial applications. The services include hot-rolled, cold-rolled, and specialty steels, meeting diverse industry requirements.

With a strong focus on quality, their products adhere to the highest industry standards, providing durability, strength, and reliability. Kenwal also prioritizes timely delivery to minimize operational disruptions and keep projects on track. Their knowledgeable and experienced team is always available to provide expert guidance and support, helping clients select the best steel solutions for their specific applications.

By partnering with Kenwal Steel, you can be confident that you’re getting the best possible steel products for your industrial applications. For a closer look at Kenwal’s capabilities and offerings, visit Kenwal Steel or call (313)-739-1000.

Looking for high-quality steel and reliable service?

Our experts are here to help you source the right steel—on time, every time.

Speak with a Steel Expert Today!

Recent Comments