In today’s fast-paced world, where environmental concerns are at the forefront of many industries, finding sustainable and eco-friendly solutions is paramount for future generations. When it comes to the steel industry, one material stands out for its exceptional strength, versatility, and eco-friendliness: ultra-high-strength steel (UHSS). Let us emphasize that ultra high-strength steel is Earth friendly! In this article, we will explore what UHSS is and how it is manufactured. Additionally, why is it the top choice for multiple industries, particularly the automotive industry.

What is Ultra-High-Strength Steel?

Ultra-high-strength steel, or UHSS, is a type of steel known for its remarkable strength properties. It is specifically engineered to possess higher strength-to-weight ratios, compared to traditional steels. This makes it the perfect material for the automobile industry. UHSS is manufactured through a precise combination of alloying elements, heat treatment, and controlled cooling processes. These techniques enhance steel’s mechanical properties. As a result, the material is both strong and lightweight.

Two Main Types of UHSS

Advanced high-strength steel (AHSS) is a category of UHSS that includes various steel grades designed for specific applications. It encompasses a range of steel types, such as dual phase (DP), transformation-induced plasticity (TRIP), complex phase (CP), and others. Each steel type within the AHSS category offers a unique combination of strength, formability, and crashworthiness properties. Therefore, this makes them suitable for a wide range of different automotive components.

High-strength low-alloy steel or HSLA, is another type of UHSS that provides high strength with improved formability compared to conventional steels. It contains alloying elements such as copper, nickel, and chromium, which enhance its mechanical properties. HSLA steel is commonly used in structural applications where strength, weight reduction, and corrosion resistance are essential.

Why is Ultra-High-Strength Steel Earth Friendly?

Ultra-high-strength steel (UHSS) is considered eco-friendly for several reasons, especially highlighting its positive impact on the environment. To know more, let’s first delve into the specific aspects that make UHSS an environmentally conscious choice:

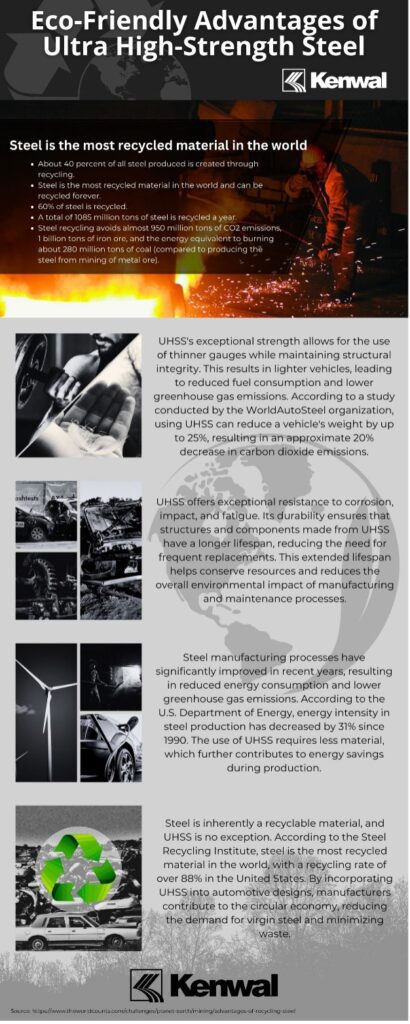

One of the key industries that takes advantage of UHSS’s amazing capabilities is the automotive industry. They saw UHSS as a game-changer in the pursuit of safer and greener vehicles by utilizing it in car manufacturing. Automakers realized massive improvements in crash safety performance while reducing vehicle weight and emissions. The numerous properties of the material allowed for innovative vehicle designs that enhance fuel efficiency without compromising safety.

Around the world, leading automotive manufacturers have incorporated UHSS into their vehicle platforms — resulting in lighter and more fuel-efficient models. By combining the lightweight design, recyclability, durability, and energy efficiency of UHSS, this type of steel presents itself as an eco-friendly choice across various industries.

Moving Towards a Clean Future: UHSS in 2023 and Beyond

With a focus on eco-friendly advancements and a commitment to the circular economy, UHSS is making significant strides in reducing environmental impact while offering numerous advantages. Let’s explore more key points that highlight UHSS’s path towards a clean future in the automotive industry:

-

Reduced environmental impact

Ultra High-Strength Steel Earth friendly properties, such as lightweight design and recyclability, lead to reduced energy consumption and greenhouse gas emissions throughout the vehicle’s lifecycle resulting in a 5% reduction in greenhouse gas emissions. New grades of ultra-high-strength steel enabled carmakers to reduce vehicle weight by 25-39% compared to conventional steel.

-

Improve lifespan

UHSS’s durability ensures that automotive components made from this steel have a longer lifespan. With these improvements in design and manufacturing, automakers contribute to reducing the frequency of replacements and conserving resources. This extended lifespan aligns with the principles of the circular economy, where products are designed for durability and longevity.

-

Electric vehicles

The electric vehicle (EV) industry has recognized the numerous benefits of ultra-high-strength steel (UHSS) and has been actively incorporating it into EV designs. EVs often require unique structural designs to ensure the robustness and crashworthiness of the vehicle and provide sufficient protection in the event of a collision.

Shaping the World with Kenwal: Their Commitment to Eco-Friendly Ultra-High-Strength Steel Solutions

With over 70 years of steel experience, Kenwal Steel continues to deliver sustainable ultra-high-strength steel solutions to diverse industries across the globe. With their heavy investments in the industry’s most sophisticated processing equipment, a dedicated team of steel specialists, and an advanced A2LA certified lab (among other resources), Kenwal is proud to hold IATF 16949 and ISO 14001 certifications for their processing and distribution facilities — a testament to their unwavering commitment to quality and sustainability.

The company continues to prioritize and invest in its operations to ensure maximum quality and uptime, meeting the needs of its customers with round-the-clock availability. Kenwal Steel’s commitment to excellence and continuous improvement guarantees exceptional service and timely delivery to its valued customers.

Learn More About Kenwal Steel

Kenwal is a leader in the steel industry with over 70 years of experience. Headquartered in Dearborn, Michigan, Kenwal Steel operates service center locations in Michigan, Indiana, and Tennessee. The company was founded with the core belief that “Quality has no ceiling,” and this is ingrained in Kenwal Steel’s culture so much so that they continuously achieve with relentless dedication — thanks to their exceptional systems, continuous research and development, and passionate employees.

Renowned as the “High-Strength Experts,” Kenwal offers an extensive inventory of ultra-high-strength steel, hot-rolled steel, cold-rolled steel, and coated steel coils among others. As a steel service center, the company provides value-added services such as slitting, pickling, steel packaging, material control and delivery, and technical support.

If you are interested in collaborating with us for all your steel needs, visit us or request a quote: https://kenwal.com/contact/. You can also call us at (313) 739-1000 or email us at [email protected].

You can also follow us on social media:

YouTube: https://www.youtube.com/@kenwalsteel2359

LinkedIn: https://www.linkedin.com/company/kenwal-steel/

Facebook: https://www.facebook.com/KenwalSteelCorp

Twitter: https://twitter.com/KenwalSteelCorp

Instagram: https://www.instagram.com/kenwal_steel/

Recent Comments