What Is Advanced High-Strength Steel (AHSS)?

Compared to traditional steel, advanced high-strength steel is a cutting-edge steel variant that represents the future of steel processing. Celebrated as the strongest steel available, AHSS exhibits unparalleled mechanical properties, boasting exceptional strength, malleability, and deformation resistance.

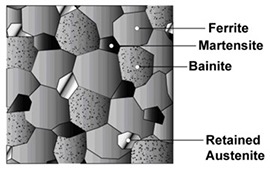

The advantages of AHSS are achieved through the integration of various steel alloys and the optimization of its microstructure. Advanced high-strength steel, in more precise terms, includes all martensitic and multiphase steels with a minimum specified tensile strength of at least 550 megapascal pressure units (MPa). This sets it apart from conventional high-strength, low-alloy HSLA steels, which typically feature a single-phase ferritic structure, occasionally accompanied by pearlite in carbon-manganese (C-Mn) steels.

Image Attribute: https://ahssinsights.org/tag/retained-austenite/

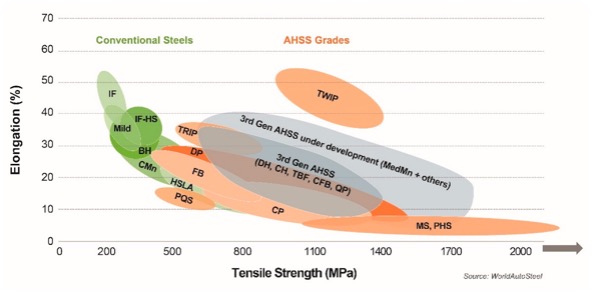

Unlike conventional steels, certain varieties of AHSS exhibit a remarkable balance between strength and ductility due to an enhanced capacity for strain hardening. Meanwhile, other types of AHSS boast ultra-high yield and tensile strengths, along with bake-hardening behaviors. These differing types of advanced high-strength steels can be identified as either first, second, or third generation, each categorized by the differences of their microstructural components.

Image Attribution: https://steelemotive.world/innovative-high-voltage-ev-battery-pack-creates-savings-all-round/

Benefits of Advanced High-Strength Steel

-

Superior strength-to-weight ratio:

AHSS provides increased strength while maintaining a lower weight profile, making it a go-to steel grade for certain industries, especially automotive.

-

Environment-friendly:

The reduced energy demands of advanced high-strength steel make it an eco-friendly choice, leading to improved fuel efficiency and a substantial decrease in greenhouse gas emissions.

-

Formability and adaptability:

AHSS retains outstanding formability, allowing for the creation of intricate shapes and designs. This flexibility adheres to a wide range of steel products across many industries.

-

Cost-efficiency:

Its diminished energy and material requirements not only promote environmental benefits but also translate into significant cost savings during both production and transportation.

Advanced High-Strength Steel Applications

Although AHSS has a long history of use in the automotive industry, it is also finding broader applications in numerous other industries. This superior class of steel has demonstrated the ability to enhance engine performance and raise speed limits in aircraft, ships, and trains. For instance, AHHS’s crash safety perks result in a material that is well suited for rail transportation systems. Oil rigs, bridge construction, civil engineering, and construction machines are also absorbing the benefits of AHSS processing.

The Promising Future of AHSS Processing

According to Market Research Reports, the global automotive AHSS market size is projected to grow from where it was in 2022 at US$16890 million to US$25600 million in 2029. Trends such as the introduction of pre-oxidation for galvanizing AHSS, as well as the development of third generation AHSS, have sparked a growing interest in the production and utilization of AHSS throughout industries.

As our steel processing experts at Kenwal look ahead to the future of AHSS, it’s clear that the steel processing industry will increasingly rely on this material. Its applications extend far beyond conventional steel, with potential uses across various industries thanks to the steel’s light weight, strength, durability, recyclability, versatility, and high corrosion resistance.

Why Trust Kenwal for Your AHSS Needs?

When it comes to advanced high-strength steel processing, trust is paramount. Kenwal’s commitment to quality, innovation, and sustainability makes us the go-to-choice for steel processing. Our dedicated team of AHSS experts is equipped to meet your specific requirements and ensure that you benefit from the full potential of AHSS.

More About Kenwal

In addition to AHSS, Kenwal has the latest grades and steel types you need to meet your most demanding manufacturing requirements. More than 70 years of working with the world’s leading steel mills means we know where to source the high-quality steel you need to meet your production schedule. Read more about the services we offer on our blog page, including top-tier production of flat-rolled carbon steel and its uses.

Recent Comments