Steel is an incredibly versatile and long-lasting material. From construction and manufacturing to transportation and energy, it has countless applications. Its varied applications are a testament to its strength and adaptability. In the realm of steel processing and distribution, steel service centers play a pivotal role.

A steel service center, such as Kenwal Steel, goes beyond being a mere supplier; it’s a crucial partner in processing and distributing steel products to a diverse range of clients including fabricators, contractors, and end users. These centers offer a range of services like cutting, bending, forming, welding, coating, painting, inventory management, and timely delivery.

Choosing the Right Steel Service Center is Key to Success

The best steel service center for your business can significantly impact your profitability, productivity, and reputation. So, it’s essential to consider several factors before making a decision. Whether you’re a small business or a large corporation, choosing the right steel service center is key to success.

While the selection of a steel service center focuses on various factors like quality, expertise, and customer service, it’s also important to understand the processes these centers use to ensure the steel’s integrity, one of which is the integral process of steel pickling.

What is Steel Pickling?

Steel pickling is the process of removing impurities, such as rust, scale, and oil, from the surface of steel by immersing it in a bath of acid. The acid dissolves unwanted substances and leaves a clean and smooth surface behind. The most common acids used for steel pickling are hydrochloric acid and sulfuric acid. This step is essential for preparing steel for subsequent processes such as galvanizing, coating, or painting. What’s more, it enhances adhesion and corrosion resistance. Steel pickling can also improve the mechanical properties and electrical conductivity of steel.

Historical Perspective of Steel Pickling in the U.S.

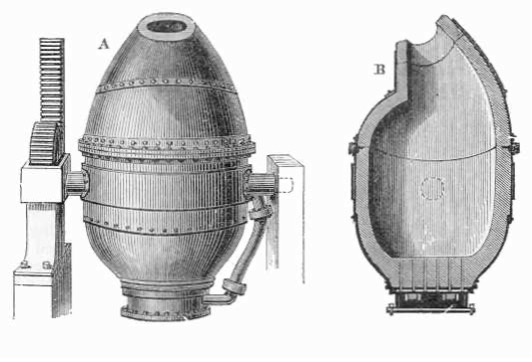

The steel industry in the United States has a long and rich history. One of the significant breakthroughs in steel production was the Bessemer process. This process made steel production quicker and less expensive by removing impurities from iron using air. There is some debate about who invented the process. Many recognize that Eber B. Ward’s Eureka Iron Works in Wyandotte, Michigan, was the first American steel mill to use the Bessemer process in 1864.

Image Attribution: https://en.wikipedia.org/wiki/Bessemer_process

The Bessemer Process

The Bessemer process emerged as a game-changer for the steel industry, leading to the growth of prominent figures such as Alexander L. Holley, Daniel J. Morrell, John A. Griswold, and Andrew Carnegie. These individuals made their fortunes after adopting the process. Detroit and Troy, New York, were considered potential candidates to become the steel capital of the world. Still, Pittsburgh, Pennsylvania, emerged as the clear winner.

Over time, the steel industry has evolved by introducing new materials and processes. New materials such as pickling and stainless steel have been developed and introduced.

Why is Steel Pickling Important?

Due to its exceptional resistance to corrosion, remarkable strength, and pleasing appearance, stainless steel finds vast applications in numerous industries. However, during the processing or fabrication of stainless steel, its protective layer can be damaged or contaminated with impurities, causing the surface to be compromised. This compromised surface is prone to corrosion, staining, and other types of deterioration, which can impact the material’s integrity and lifespan.

It’s a fundamental step in producing, handling, and maintaining stainless steel products, underscoring its importance in the industry and in applications where high-quality steel is essential.

Kenwal Steel’s Expertise in Steel Pickling

A North American steel service provider based in Michigan has met this need for decades, providing a broad range of steel applications and a state-of-the-art Michigan steel pickling operation. With its expertise in automotive steel processing and a commitment to delivering top-quality products, this Michigan-based steel service provider has become a go-to choice for many businesses in the industry. Consequently, Kenwal is helping to meet the growing demand for high-quality steel products.

Kenwal is proud to offer a computer-controlled push-pull steel pickling line and in-line tension-leveling process that produces the highest quality pickled & oiled steel possible. With a pickling line facility that shares space with one of their steel slitting locations, processing the entire coiled steel order is done fast and efficiently, ensuring customers get the pickled & oiled steel they need when needed.

Customers looking for pickled and tension-leveled steel for their production needs can trust Kenwal to ship only the highest quality flat-rolled steel, chemically treated to remove imperfections and ready to use on their manufacturing lines.

The Technical Expertise and Experience of the Staff at Kenwal Steel

It is essential to work with friendly and experienced professionals who deeply understand the steel industry and are passionate about their craft. Their passion and expertise ensure that customers receive the best possible service and support, contributing to Kenwal’s reputation as a leader in the field.

State-of-the-Art Equipment and Technology

At Kenwal, the use of advanced equipment and technology in processing and testing steel products is a key focus. They employ the most modern tools and methods, ensuring that their customers receive high-quality steel products efficiently and quickly.

Strategic Locations and Efficient Delivery

Kenwal has facilities near major highways and waterways in Dearborn, Michigan. It is easily accessible by rail for maximum delivery efficiency. Their material handling and delivery personnel work closely with customers to determine their best delivery options with speed, cost-effectiveness, and convenience in mind.

A Company That Puts You First

Lastly, you want to find a steel service center that puts you first and helps you find the right products for your needs. Kenwal prioritizes understanding and meeting the needs of their clients, ensuring a service that is not only responsive but also supportive. This commitment to customer care has earned Kenwal a loyal customer base that values their consistent and reliable service.

So, if you’re in the market for steel products, consider Kenwal Steel as your trusted partner. Visit their website or contact their team to learn more about their products, services, and commitment to sustainability.

More About Kenwal Steel

Founded in 1947, Kenwal Steel is a world-class steel service center recognized as a Top 20 steel service and distribution company. With locations in Dearborn, Michigan; Burns Harbor, Indiana; and Lebanon, Tennessee, the company operates state-of-the-art facilities that consist of seven steel slitting lines and a high-volume pickling line with in-line tension leveling.

Kenwal Steel’s tooling, metallurgy, and material handling teams are highly skilled and committed to providing the highest service to customers in the automotive and manufacturing industries. They optimize material specification and sourcing to meet customers’ exacting standards and deliver the highest quality rolled steel. The company is committed to excellence and strives to provide its valued customers with the best service possible.

Follow Us on Social Media:

YouTube: https://www.youtube.com/@kenwalsteel

LinkedIn: https://www.linkedin.com/company/kenwal-steel/

Facebook: https://www.facebook.com/KenwalSteelCorp

Twitter: https://twitter.com/KenwalSteelCorp

Instagram: https://www.instagram.com/kenwal_steel/

Recent Comments