Key Takeaways

- Lightweighting steel improves fuel efficiency, performance, and sustainability across automotive and manufacturing industries.

- Advanced materials like AHSS and UHSS enable thinner, stronger components without sacrificing safety or durability.

- Precision processing reduces material waste and enhances design flexibility — making Kenwal Steel a trusted partner in delivering high-quality, lightweight solutions.

Lightweighting steel is transforming the automotive and manufacturing industries. It delivers better performance, improved fuel economy, and long-term cost savings. By reducing the weight of steel components without sacrificing strength, manufacturers gain efficiency and advance their sustainability goals.

This innovation also reduces material usage and environmental impact — two priorities for today’s forward-thinking OEMs and suppliers.

The Core of Lightweighting Steel

The push for lighter, stronger materials is fueling the demand for lightweighting steel. One of the biggest breakthroughs is the development of innovative steel compositions that reduce density while maintaining durability.

According to Science.org, researchers have created a new lightweight steel that is cost-effective and exceptionally strong, making it a viable alternative to traditional materials. This lets manufacturers lower the weight of vehicles and equipment while keeping structural integrity intact.

The Role of Advanced High-Strength Steel in Lightweighting

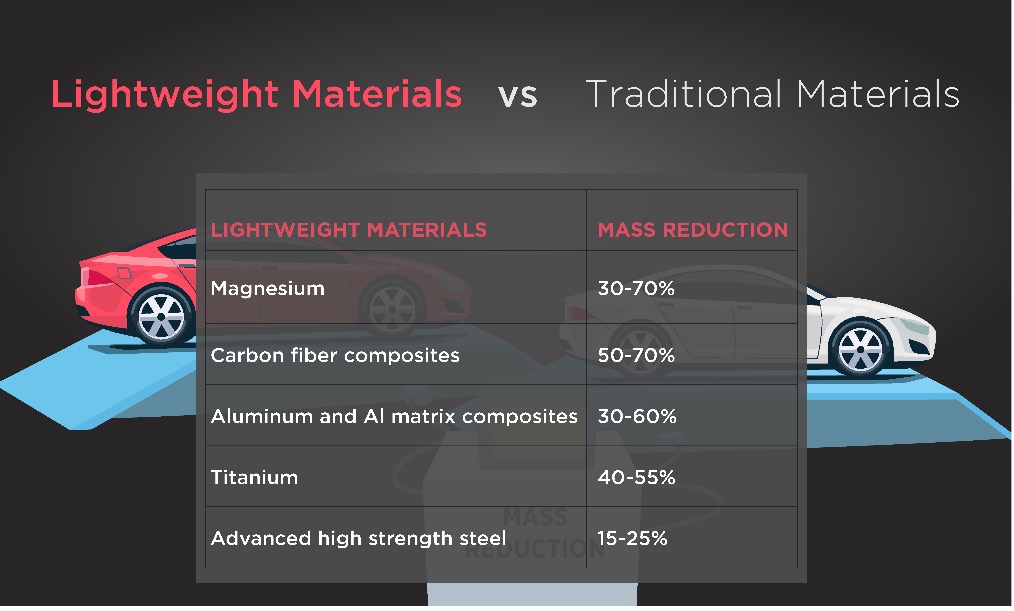

In manufacturing, lightweighting means reducing product weight through smarter design and material choices. When it comes to steel, this involves using advanced high-strength steel (AHSS). AHSS is a material that delivers a high strength-to-weight ratio without compromising structural performance. These steels allow manufacturers to design thinner, lighter components that maintain — or even enhance — durability and safety standards.

The U.S. Department of Energy reports that cutting just 10% of a vehicle’s weight can boost fuel efficiency by 6% to 8%. This makes lightweighting steel a smart, strategic move for OEMs aiming to meet fuel economy targets while improving sustainability across their operations.

Advancements in High-Strength, Low-Weight Steel Grades

Lightweighting steel continues to evolve with the development of advanced high-strength steels (AHSS). These steels are lighter and stronger than traditional grades, giving manufacturers a clear edge in designing more fuel-efficient, high-performing vehicles. AHSS has become one of the most effective automotive steel solutions available today.

Engineers achieve these advancements by precisely controlling the steel’s microstructure and adding alloying elements such as carbon, manganese, and silicon. Designers develop high-strength, low-alloy (HSLA) steels to improve their mechanical characteristics and corrosion resistance, making them suitable for challenging applications in the automotive and manufacturing industries.

Pushing the Limits with Ultra-High-Strength Steel

The introduction of ultra-high-strength steels (UHSS) has taken lightweighting steel to new heights. These materials are processed with specialized heat treatments and alloying techniques to achieve exceptional strength levels. The result? Lighter, thinner components that still meet strict safety and performance standards.

This evolution in high-strength steel for automotive applications supports industry goals around safety, fuel efficiency, and sustainability. These advancements are done without compromising design flexibility or structural reliability.

Minimizing Material Usage

Lightweighting steel isn’t just about new alloys; it also depends on how steel is processed. Precision techniques reduce material usage while maintaining performance. These methods are key to advancing steel for manufacturing applications.

Processes like controlled rolling and thermo-mechanical treatment refine the grain structure of steel. This improves strength and allows manufacturers to use thinner gauges without sacrificing durability. The result? Stronger, lighter components that use less material.

Modern forming technologies also support lightweighting efforts. Techniques like roll forming and hydroforming allow for the creation of complex, accurate shapes with minimal waste. These methods enhance dimensional precision, reduce weight, and improve overall product performance. By integrating precision processing into their operations, manufacturers lower material waste, boost efficiency, and move closer to their sustainability goals.

Benefits of Lightweighting in Automotive and Manufacturing

The adoption of lightweighting strategies yields numerous advantages across various facets of automotive and manufacturing industries. Understanding the benefits of steel lightweighting in vehicle manufacturing helps manufacturers optimize designs for efficiency, sustainability, and cost-effectiveness.

-

Fuel efficiency and emissions reduction: Lighter vehicles require less energy, improving fuel economy and reducing greenhouse gas emissions. Research from NIST highlights how advanced lightweight materials in automotive design help manufacturers meet stringent fuel efficiency standards while maintaining safety and performance. This is particularly important as sectors aim to comply with strict environmental standards and address consumer preferences for more eco-friendly products.

-

Enhanced performance and safety: Reducing vehicle weight improves handling, acceleration, and braking performance. Using AHSS and UHSS helps uphold safety standards, as these materials offer superior crashworthiness and durability.

-

Cost savings: Lightweighting can lead to lower material and transportation costs. Manufacturers can achieve significant economic benefits over a product’s lifecycle by using less material and improving fuel efficiency.

-

Sustainability: Employing lightweight materials contributes to resource conservation and reduces manufacturing processes’ environmental impact. This corresponds with worldwide initiatives to encourage sustainability and lower carbon emissions.

Steel Supplier for Your Lightweighting Solutions

Kenwal Steel recognizes the critical importance of lightweighting in the competitive market. With over 70 years of experience, the company remains committed to delivering high-quality flat-rolled steel products that satisfy the specific needs of the automotive and manufacturing industries. Kenwal’s expertise in sourcing and processing advanced steel grades ensures that clients receive materials that meet the highest strength, durability, and weight optimization standards.

Before you go, download Kenwal’s corporate overview to learn more about their capabilities and locations. Ready to take the next step? Contact Kenwal Steel today to discover how their lightweighting solutions can drive your success.

Ready to take the next step?

Discover how their lightweighting solutions can drive your success.

Speak with a Steel Expert Today!

Recent Comments