Kenwal, the leader in automotive steel processing, is here to explain why steel has remained the key material in the automotive industry over the years. It has a wide range of yield strength with a high modulus of elasticity. Steel is also considered the most preferable material by many automotive steel processors due to its high strength, durability, and low cost.

Advanced High-Strength Steel

Sheet steel with 340 MPa or more is called high-strength steel. The process of strengthening involves a variety of methods. There are several benefits to using steel in automotive production, according to worldsteel.org. Steel usually contains recycled steel and is infinitely reusable. It has lower CO2 life cycle emissions than any other automotive material.

Because of the American steel industry’s investments in cutting-edge materials and manufacturing techniques, a wide range of high-quality automotive steel is now available. These advanced high-strength steels (AHSS) are stronger, lighter, and produced with simple life cycle impact, helping automakers decrease a vehicle’s life-long carbon footprint. The United States excels in advanced high-strength steel (AHSS), providing customers with expertise, choice, and a strong commitment to American values.

Advantages of Steel on Automotive Steel Processors:

- It contains recycled steel and is endlessly recyclable.

- It has lower CO2 life cycle emissions than any other automotive material.

- Enables engineering of crash-resistant structures.

- High-strength steels enable light but durable vehicles.

- Lightweight, therefore fuel efficient.

- Tough and remanufacture-friendly.

- Enables creative, flexible designs.

- Enables affordable repairs.

- Cost-efficient compared to other materials.

- Well-established manufacturing and recycling infrastructure and workforce.

Advanced High-Strength Steel: Toward a Sustainable Future

Furthermore, advanced high-strength steels (AHSS) are a class of high-performance steels essential to many American steel processors due to the increased need for fuel efficiency, emissions reduction, and passive safety. Because it can create lightweight constructions that cut down on energy use and harmful emissions, advanced high-strength steel is being employed more and more in the automobile sector.

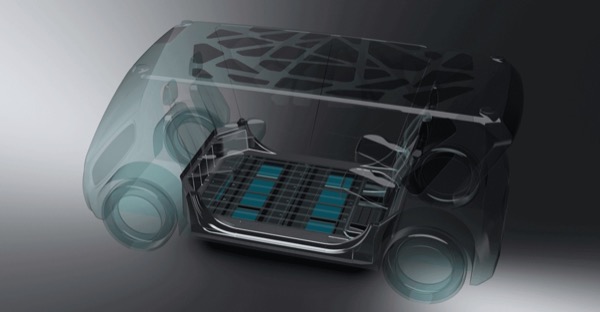

The Steel E-Motive project demonstrates the suitability of the latest advanced high-strength steel grades for use in fully autonomous electric vehicles.

Image Attribution: https://steelemotive.world/innovative-high-voltage-ev-battery-pack-creates-savings-all-round/

News and Market Trends

The global advanced high-strength steel (AHSS) market stands at US$ 18.16 billion in 2022 and is anticipated to grow at a CAGR of 12.3% over the following six years to reach US$ 40.36 billion by 2029. An analysis by FACT.MR predicts that by 2030, the demand for advanced high-strength steel (AHSS) will grow at a steady 8.5% CAGR. In fact, the automotive industry is one of the biggest industries that use AHSS in their products.

Here is Why:

- The need to lighten vehicles up to improve their performance and safety is expanding globally, and North America is one of the biggest markets for AHSS. As a result, the fastest-growing material in the modern automobile industry is advanced high-strength steel (AHSS) which is essential for mass vehicle reduction.

- About 70% of the weight of a typical automobile is steel. For a regular passenger automobile, this equates to 165 to 250 kg less weight than the standard steel, which reduces greenhouse gas emissions of 3 to 4.5 tons throughout the vehicle’s lifetime. This emission reduction is far more exceptional than the CO2 released during the steel production process required to make a car.

- The production of gasoline and diesel engines may experience negative growth as electric vehicles proliferate and diesel vehicles are increasingly outlawed. The market for alternative fuel cars uses AHSS; therefore, it will continue to be a driving element.

Kenwal: Setting the Standard for Automotive Steel Processing

Kenwal Steel is one of your leading North American steel services providers that offer over 70 years of experience in flat-rolled automotive steel processing, including advanced high-strength and galvanized steel. Routinely recognized as one of the top 50 steel service and distribution companies, Kenwal has embraced modernization by enhancing their processes through our specialized slitters for AHSS slitting. Kenwal’s commitment to innovation is propelling them forward in the ever-evolving world of steel production.

In an era where industries are clamoring for greener and leaner AHSS solutions, steel industry goliaths like Kenwal continue their history of high-quality steel service in redesigned facilities made expressly for AHSS cut-to-length processing. Due to our dedication to the future of steel, the auto industry, and the environment, Kenwal Steel can uphold its reputation as a leading automotive steel processor and the overall best steel service provider.

We are committed to providing our customers with the highest quality flat-rolled carbon steel and services. Call us at (313) 739-1000 or contact us via our website to learn more about how we can help you with your automotive steel needs.

About Kenwal:

Kenwal Steel has become a leading flat-rolled steel service center in North America. The company caters to industries such as automotive, appliances, agriculture, heavy equipment, industrial manufacturing, and tubing. With over 70 decades of experience in the steel industry, we specialize in providing their customers with high-quality products and topnotch steel services. Kenwal’s commitment to customer satisfaction is the driving force behind our exceptional performance and growth. Kenwal’s steel service centers are located in the United States and Canada, specifically: Michigan, Tennessee, Northwest Indiana, and Ontario Canada.

Follow Us On Social Media:

YouTube: https://www.youtube.com/@kenwalsteel

LinkedIn: https://www.linkedin.com/company/kenwal-steel/

Facebook: https://www.facebook.com/KenwalSteelCorp

Twitter: https://twitter.com/KenwalSteelCorp

Instagram: https://www.instagram.com/kenwal_steel/

Recent Comments